ABOUT LANMIN

20 Years’ Experience in Custom Casting & Stamping Parts Manufacturing

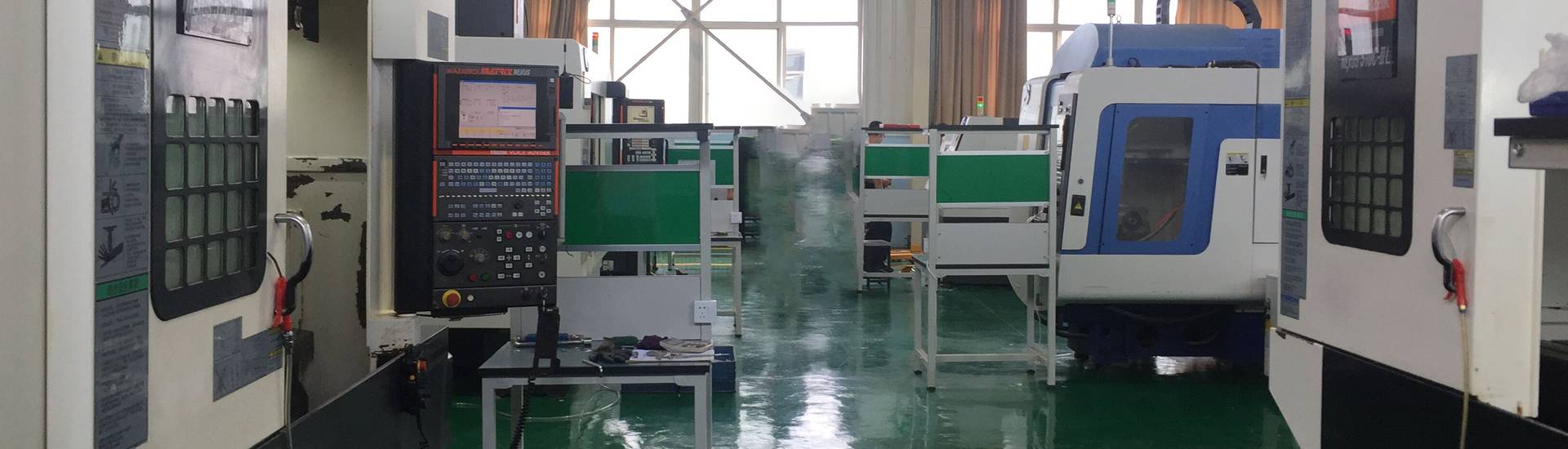

Founded in 1999, Hebei Lanmin Trading Co., Ltd. is a professional casting & stamping parts manufacturer & exporter. With over 20 years of development, we have passed ISO 9001:2008 quality management system certification and established a complete set of quality assurance system. Our casting and stamping parts are widely used in automotive, transportation, communications, electronics, aviation, shipbuilding, construction equipment, pump valve, compressor, mining machinery, engineering machinery, farm machinery, food machinery, instrument and apparatus industries, etc.

As a rich-experienced, leading casting & stamping parts manufacturer, we can produce a wide range of castings & stampings in compliance with GB, ASTM, AISI, EN 1706, DIN, BS and JIS standards. In addition, we can also customize castings and stampings in various sizes and shapes according to drawings or samples you provide.