Stamping Parts Made of Carbon Steel, Stainless Steel, Aluminum, Etc.

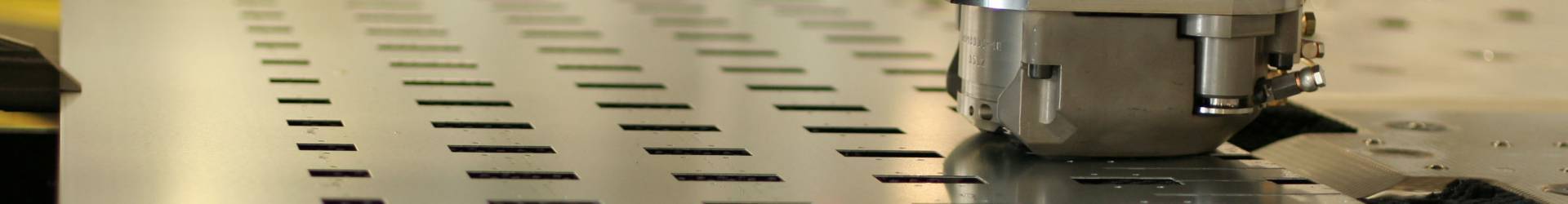

Stampings refer to workpieces obtained by using stamping presses and dies to transform sheet metal, strip metal, pipes and sections into desired shapes and sizes. Punching, blanking, bending, coining, embossing, and flanging are all stamping techniques used to shape the metal. Compared with castings, stamping parts are characterized by thin thickness, uniform texture, light weight and high strength.

Stamping parts are generally made of carbon steel, stainless steel, aluminium., brass, titanium and are widely used for automotive, industrial machinery, electronics, hardware and furniture decorations.

Features

- Stamping parts are characterized by lightweight and excellent rigidity with less metal consumption. When the sheet metal goes through plastic deformation, its internal structure is greatly improved, making the strength of stamping parts greatly improved accordingly.

- Stamping parts have high dimensional accuracy and identical sizes and can meet general assembly and operating requirements without further mechanical processing.

- In the stamping process, the metal surface is not damaged and maintains great surface quality with smooth and beautiful appearance, which creates an excellent condition for painting, electroplating, phosphating and other surface treatments.