Expandable Pattern Casting for Castings with Complex Geometrical Shapes

Expandable pattern casting, also known as green casting, lost foam casting or expandable casting process, is a new casting process for producing complex, close-tolerance castings. Foam models similar in size and shape to the casting are bonded into model clusters. After being brushed with refractory coating and dried, the foam models are buried in quartz sand and vibrated for modeling. The model is vaporized by casting under negative pressure, and the molten metal occupies the position of the model. Then castings are formed after solidification and cooling.The final shape and size of metal casting are exactly the same as the model.

Features

- Castings have accurate size and shape with great reproduction capacity. In addition, it has high surface finish just like precision casting.

- It reduces the sand core and core making process, thereby eliminating casting defects and waste products caused by core making and core setting.

- It adopts dry sand molding without binder, moisture and any additives, thereby eliminating casting defects and waste products caused by moisture, additives and binders.

- It greatly simplify the sand processing system , allowing all molding sand can be reused.

- Casting orifice with reasonable shape can be set in the ideal position, eliminating restrictions arising from traditional factors such as parting and mold taking, thus reducing the internal defects of the casting.

- Combined pouring and multiple parts in one box greatly improve the production efficiency of castings.

- It reduces the processing allowance and lower the processing cost.

- Mechanized automatic assembly line production can be easily realized. The production line has great elasticity, making the production of castings made of different alloys into different shapes and sizes possible in one production line.

- It reduce dust, smoke and noise pollution and greatly improves the working conditions of foundry workers.

- It is not only suitable for castings with simple geometrical shape, but also for castings with multiple open edges, multiple cores, and complex geometric shapes that are difficult to start with ordinary casting.

Casting Gallery

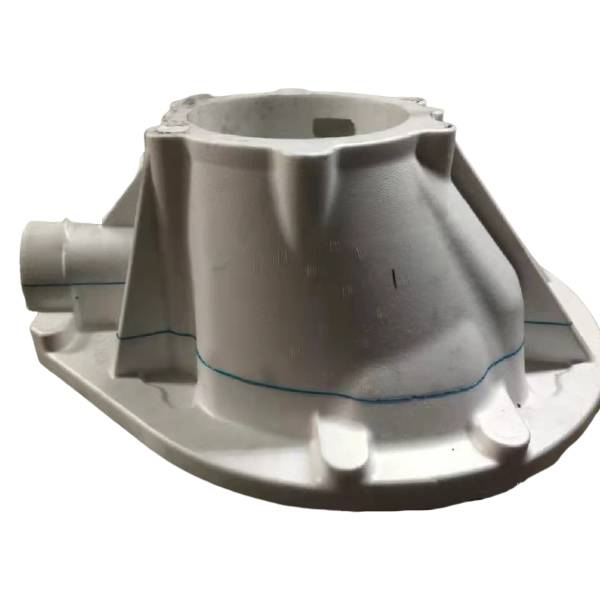

Gray iron pump body white mold

Ductile iron differential

White mold and accessories